If you own or are employed by a company that utilizes scales as part of its daily operations, then you already know the importance of having scale systems that are highly accurate. In the rail industry, high-quality rail scales help to control company costs and boost safety expectations across the board, from monitoring the weight of product deliveries to avoiding the steep fines that are associated with overloading penalties. It is vital to the function of these types of operations that rail cars and trains are weighed accurately.

The accuracy of your scale system almost entirely depends on the quality and reliability of the system being employed. One of the best ways to achieve this high standard of quality is to implement recent technology — namely, the rail scale. Rail scales are highly advanced pieces of equipment and are surprisingly intuitive in their operation. Several industries have recognized the value of these advanced scale systems, including agricultural operations and mining industries.

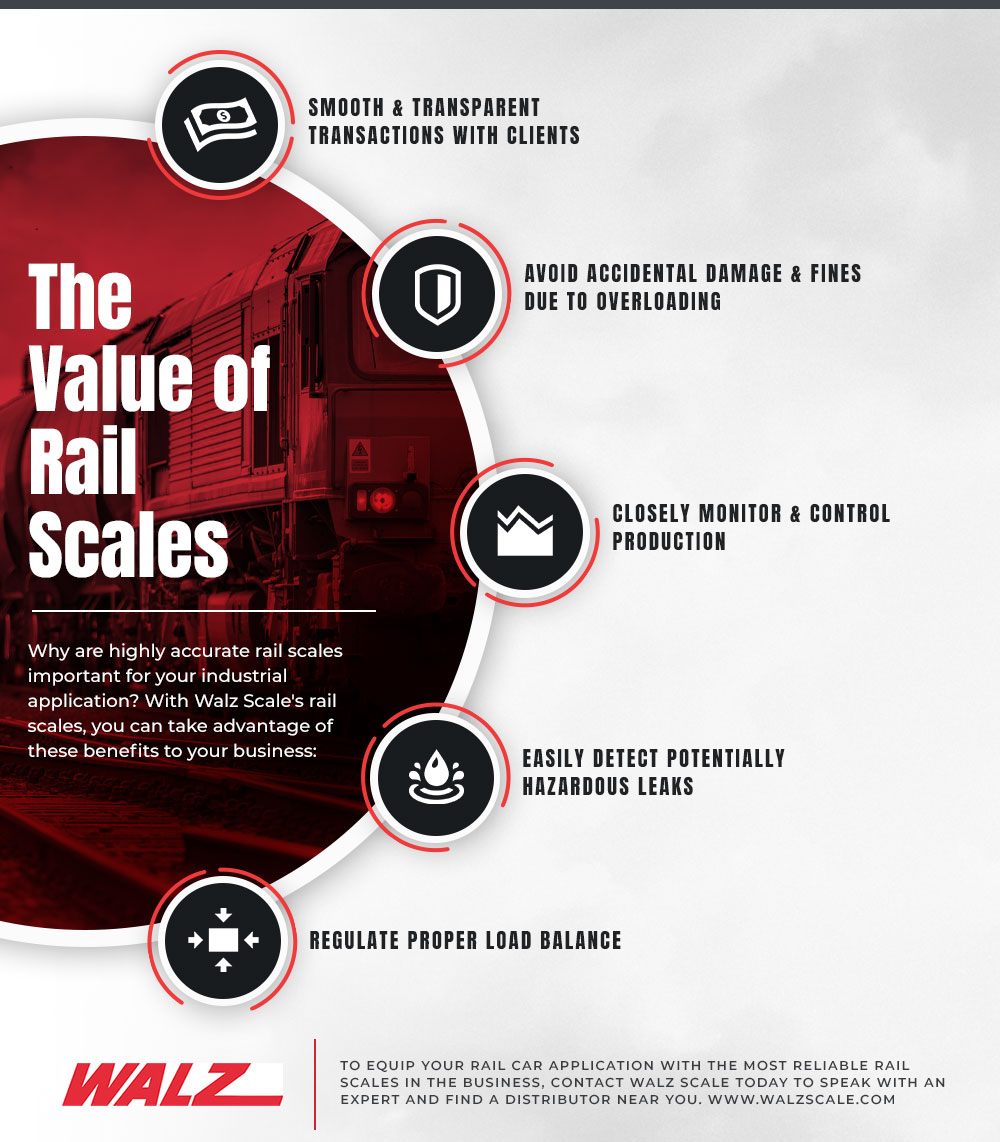

If you’re in these industries, then you know that accurate scale data is important, but you may not know exactly why these scale systems are important. To help make the importance of these scale systems clear, Walz Scale has put together this list of six reasons why implementing our high-quality rail scale systems is a smart decision for your business.

Smooth and Transparent Transactions

A properly functioning and accurate rail scale will help your company maintain smooth transactions between you and your clients. Your clients will appreciate that you’ve taken every effort to only charge them for the exact amount of the product that is being shipped. Whenever companies try to charge their clients based on estimation or approximation of product weights, this is a quick way to lose business, or at least loss of their faith in your business practices. When you use accurate weighing scales to determine the exact weight of products, you’re ensuring that your client base will be satisfied with your diligence in making sure you’re not overcharging them. This also works with the shoe on the other foot — your company can make use of your rail scale to make sure that you’re not being overcharged by a shipper.

Avoid Damage and Fines from Overloading

When railcars are overloaded, you do so at your own risk. Overloaded cars pose a serious threat to infrastructure since they are an accident waiting to happen. Overloaded cars can even be the reason that a train derails, endangering human lives in the process. It is essential that companies are responsible when it comes to preventing overloading. The single most-effective way to prevent overloading is by implementing a dependable rail scale system to assure that each rail car is being loaded within set limits. Taking this precautionary step greatly minimizes the risk of transporting high-impact loads, especially when they could encounter rail crossings, joints, and other track discontinuities.

Monitor and Control Production

Rail scales are invaluable when it comes to monitoring production and maintaining control over inventory. The more bulk items or materials that you transport, the more vital this scale system capability is for your application.

Assist in Load Control

Rail scale systems allow you to be able to take control of the rail car loads. With highly accurate scales, you can adjust the flow of materials that are being loaded, particularly during automated bulk loading. Taking advantage of this means that you can maximize each of your payloads, and further reduces the instances of overloading.

Leak Detection

Being able to compare weight data from point A to point B allows you to detect if there is a leak, which is especially important if your cargo happens to be hazardous. This weight inconsistency can be detected immediately upon arrival at a distribution center with a rail scale, helping to prevent potentially dangerous situations before they escalate out of control, putting people and property at risk.

Regulate Proper Load Balance

The advanced data that is recorded with the help of rail scales can be implemented to help operators balance loads properly in order to achieve the best-possible railcar traction and weight distribution. Coupled with the advanced technology afforded by the Walz volumetric railcar scanning system, and your load distribution and efficiency numbers will go through the roof.

Trust Walz Scale For Your Rail Scale Solution

Having explored the multiple ways that rail scales are important for rail industries, you can see why having a high-quality rail scale system is critical for achieving peak performance and efficiency. If your company deals with heavy loads that depend on railways for transportation, then Walz has a rail scale solution that will work for you. Contact us today to speak with a rail scale expert and receive a quote on your scale system today. We look forward to hearing from you and helping your business reach its maximum potential!